Check Sheets | Meaning | Classification | Construction

Table of Contents

What is a Check Sheet?

Check sheets are nothing but forms that can be used to systematically collect data. Check sheets give the user a place to start and provides the steps to be followed in collecting the data. It also helps the user in organizing the data collected so that it can be used later.

With the help of the data collected by using check sheet, histograms, pareto charts, control charts etc., can be drawn. The important feature of a check sheet is that it is very easy to understand and use. It also presents a clearer picture of the problem so that one can talk about the problem with facts.

Classification of Check Sheets

The check sheets that are currently used in the industry can be broadly classified into three types, they are as follows:

- Defect location check sheet

- Tally check sheet

- Defect cause check sheet

We will study about the above mentioned check sheets one after the other.

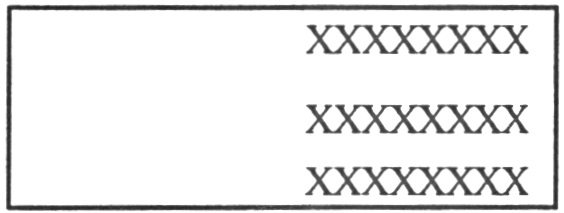

1. Defect – Location Check Sheet

Defect-Location check sheet is basically a sketch, drawing a picture of the product being made. The location in which the defect or the problem occurs is marked on the picture. An example is given in the figure below.

The above figure shows a rectangular steel sheet that was polished. We can find from the figure that in the right hand side bottom of the sheet a number of crosses denoting a particular area that has not been polished properly.

So, in this method we go in for a cross in the sketch in those areas where we think the shining is not adequate. Later, one can find the reasons for the particular error and take steps to rectify it.

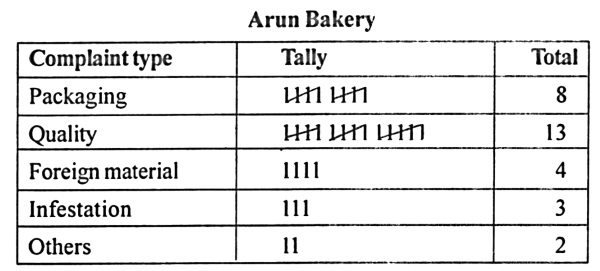

2. Tally Check sheet

A tally check sheet is helpful in finding the frequency of occurrences of various types of defects. From this, we can find out which particular defect occurs more frequently. Then, reasons for the particular defect can be found out and steps taken to rectify it.

The table given below shows the various complaints that were received by a bakery regarding its cake. From this, the major reason can be found out and steps taken to improve it.

We could understand from the above table that the main reason for customer complaint is the quality of the cake.

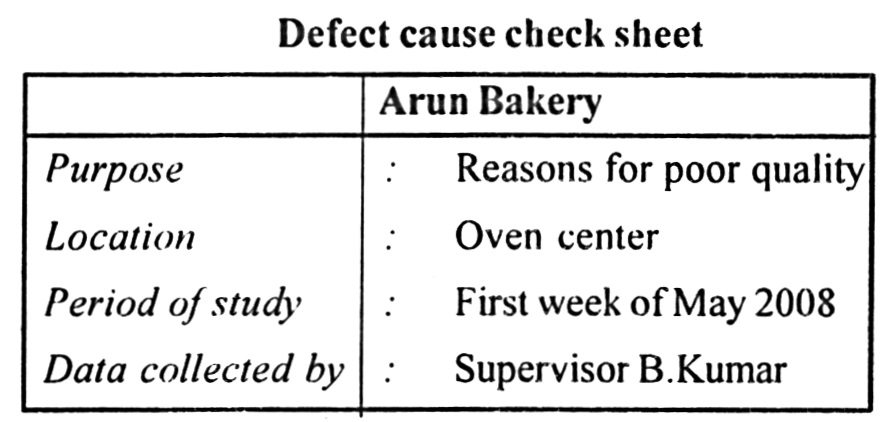

3. Defect Cause Check Sheet

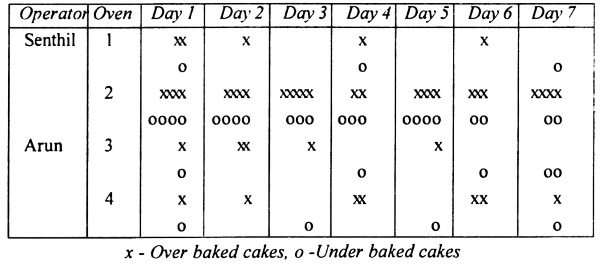

The check sheet that we used earlier helps us to find the general cause for any problem. But if one wants to know the specific reason for a particular problem, then one has to go in for a defect cause check sheet. The same example mentioned above can be taken and by using it, the exact reason for poor quality can be found out

From the above table, we can infer that the cakes produced by the operator Mr. Arjun did not meet the required quality. Large number of defects had occurred when he had gone for oven number 2 and when he had gone for oven number 1, the defects were very less. So, the real problem lies with the oven number 2.

Further study had showed that once the particular oven was serviced and a few parts replaced, the quality can be further improved upon.

Construction of a Check sheet

1. Identify the problem area

2. Identify the different types of defects that could occur. This can be achieved by forming a team and going in for a brainstorming session. A few more parameters can also be added during the data collection process when the respondents give parameters that were not identified by the team.

3. Design the form, such that it is easy to use

4. Prepare a schedule for collecting the data

5. Go about collecting the data

6. Summarize and analyze the check sheet.