Important Stages in Vendor Selection and Evaluation

Table of Contents

Stages in Vendor Selection and Evaluation

The following are the important stages in selection and evaluation of vendors.

1. Survey Stage

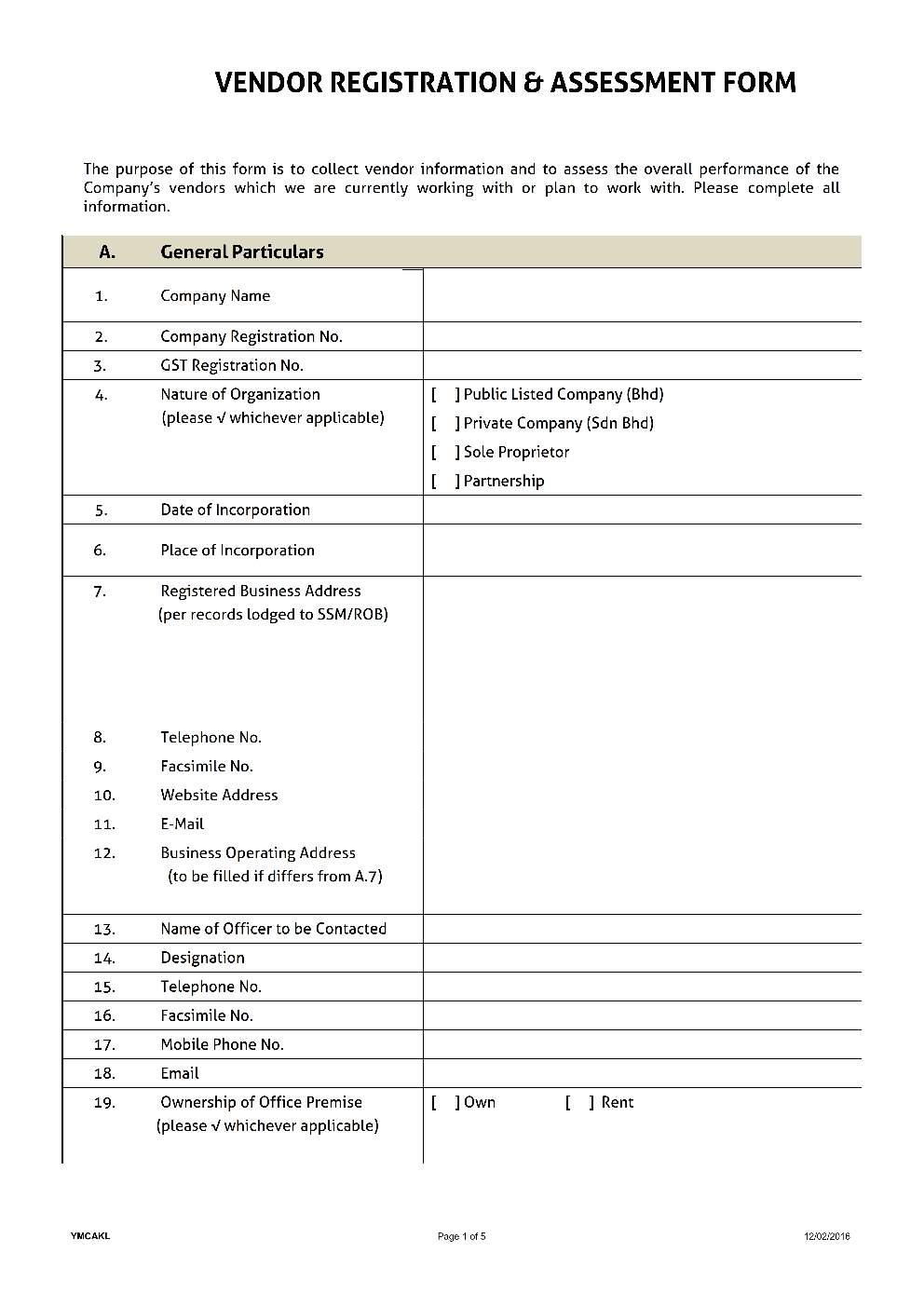

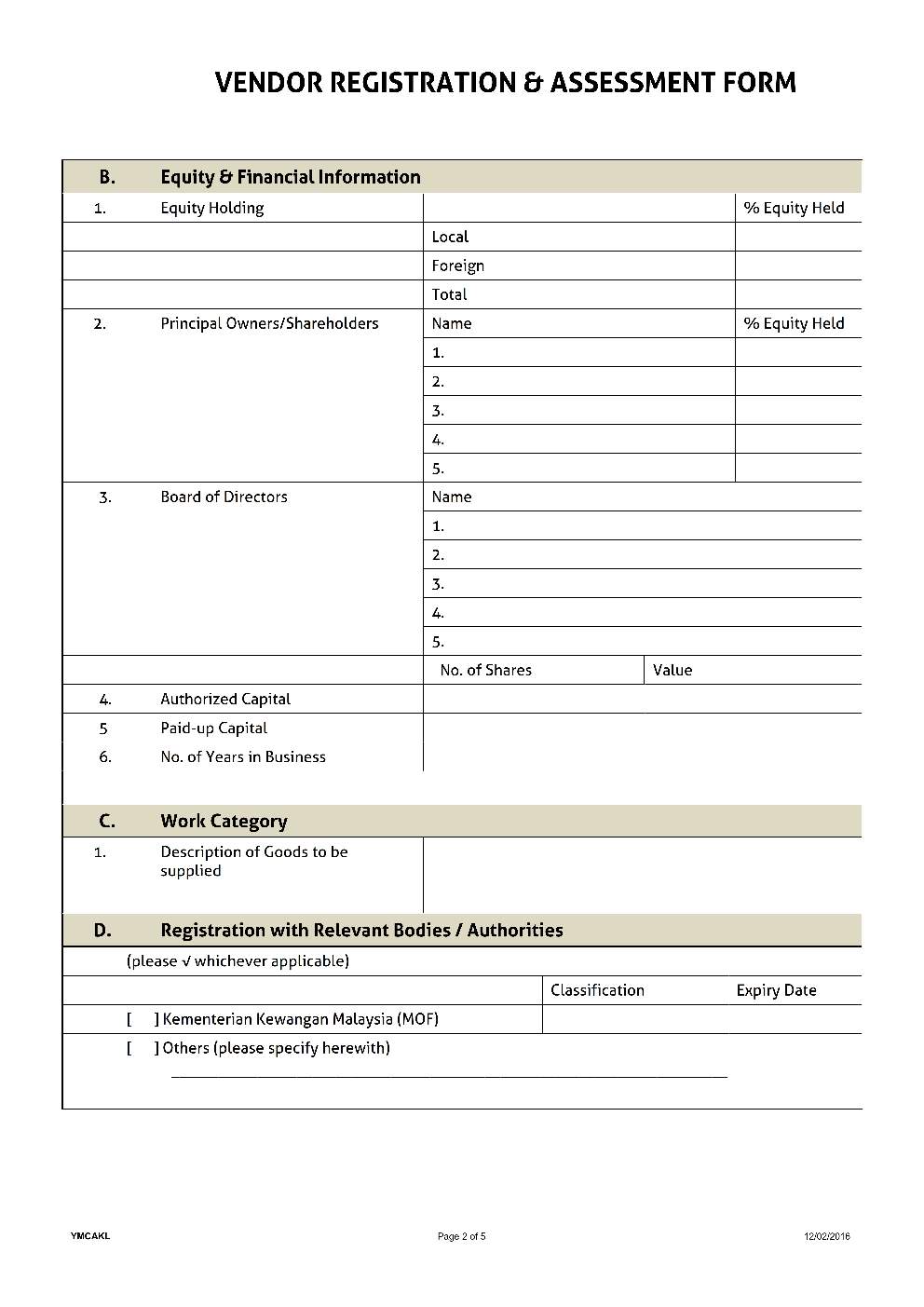

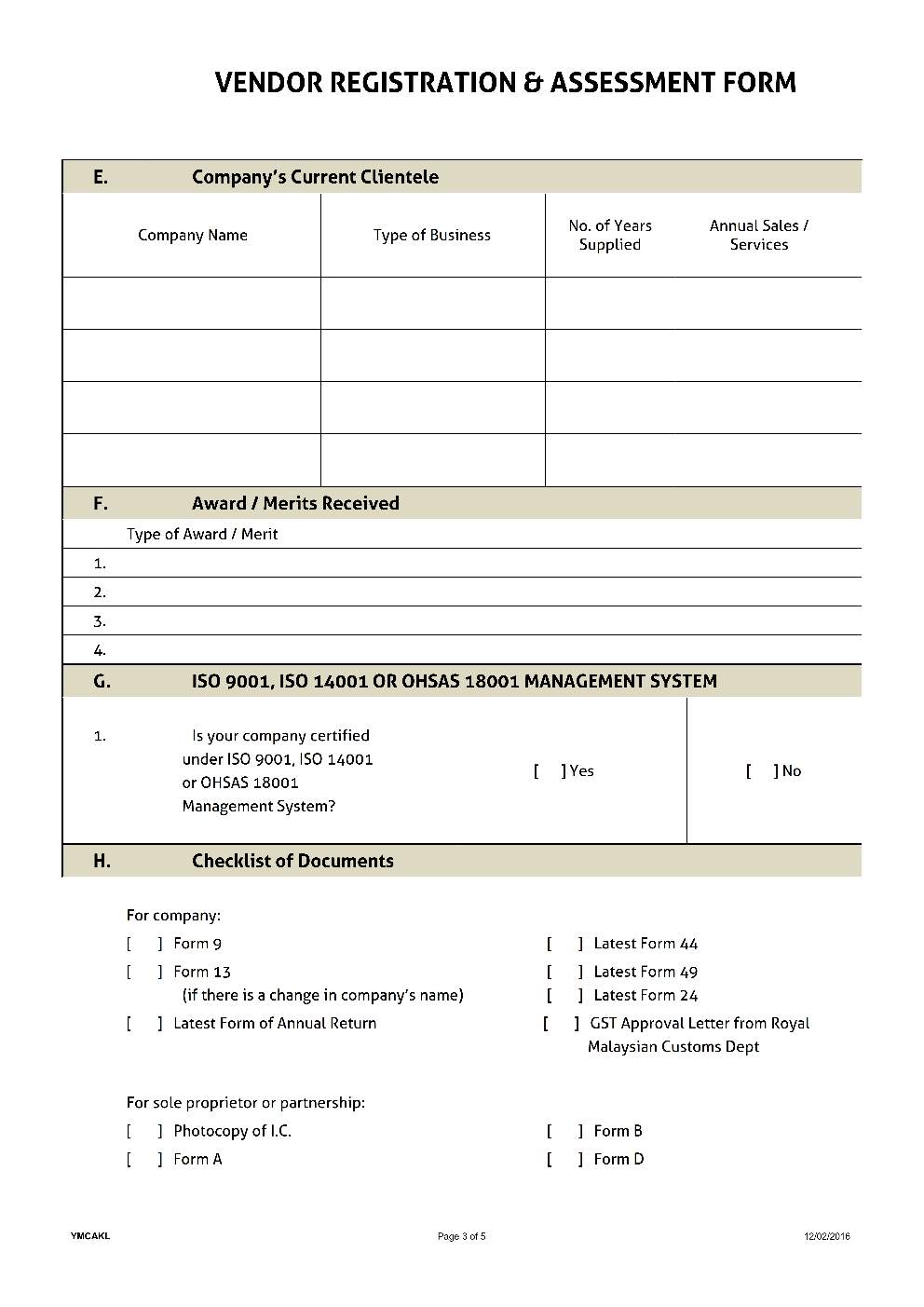

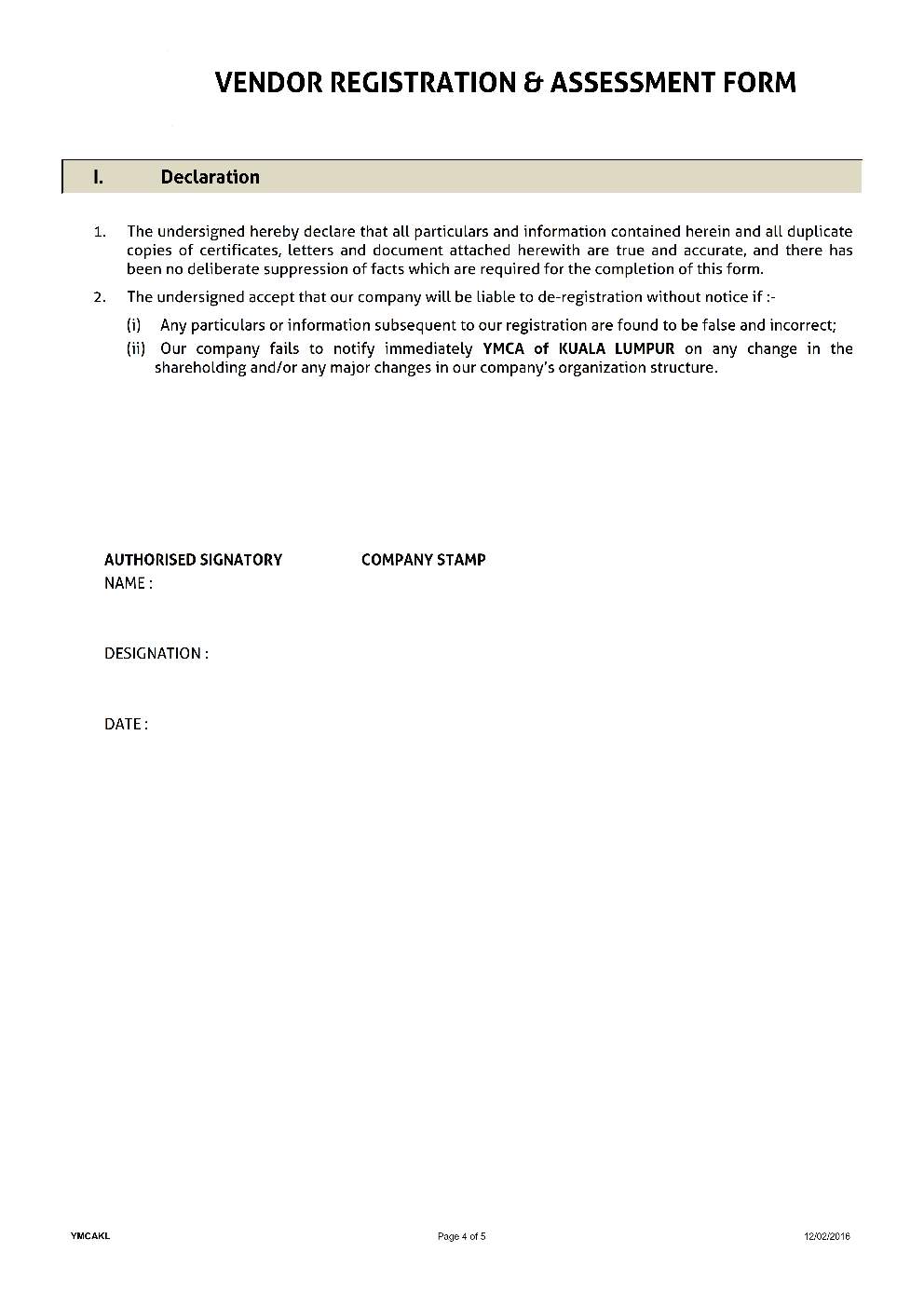

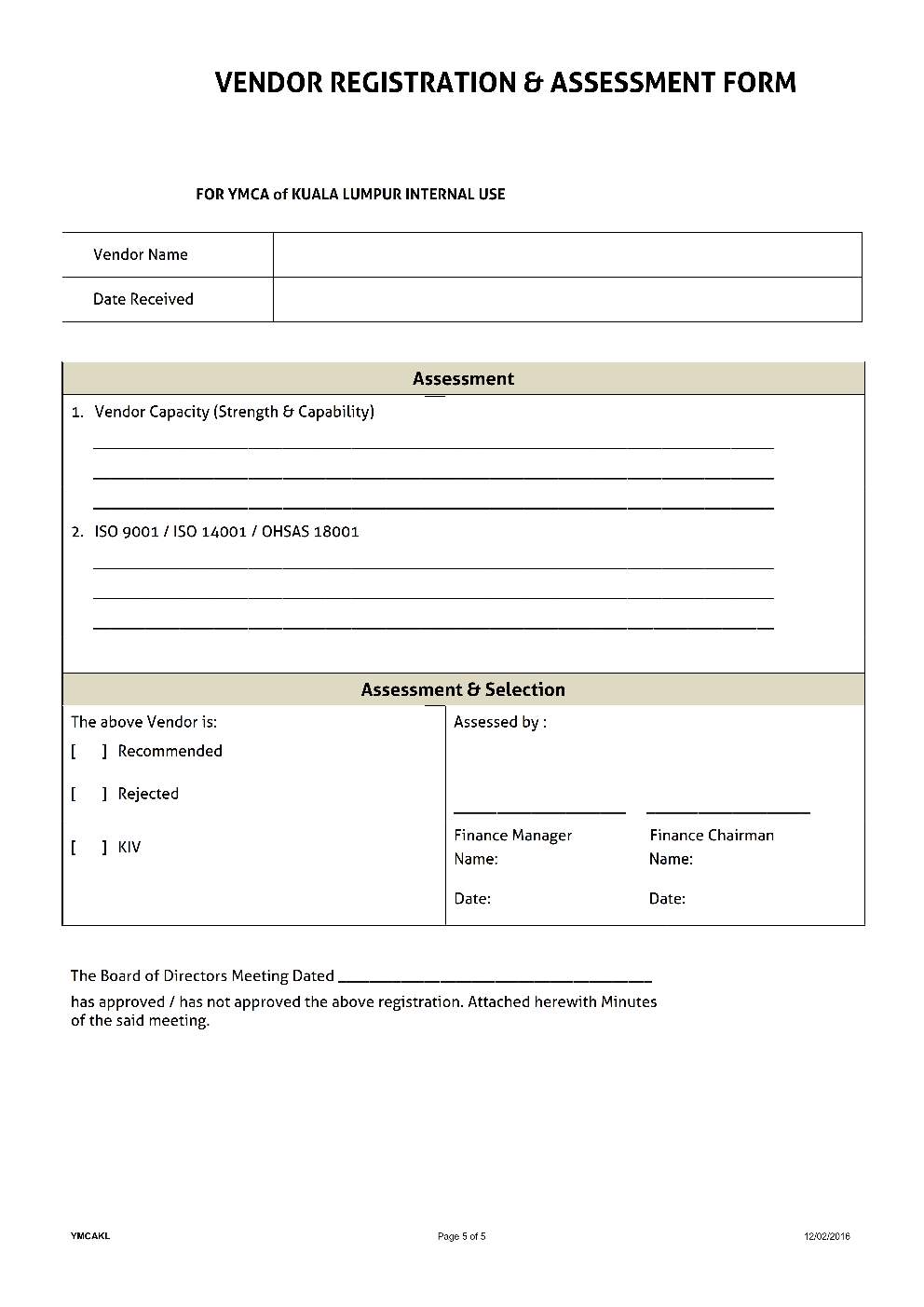

All possible sources are explored and their capabilities are evaluated on the basis of prima facie information either supplied by the vendor himself or through advertisements, catalogues, brochures, etc. A list is drawn up of those who have to be investigated further. Many companies keep a list of approved suppliers. A vendor wishing to be considered for such registration has to apply in a special form called Supplier Registration Form.

Model Vendor Registration and Assessment Form

2. Enquiry Stage

A detailed analysis is made after obtaining as much relevant information as is necessary. The vendor may be asked to furnish information in a standard enquiry form and this may be followed by a plant visit, if necessary. Enquiries may be made of his/her existing customers for ascertaining his/her performance.

3. Negotiation and Selection

The enquiry stage may reveal that quite a few of those considered at the survey stage do not come up to expectations. Those vendors who pass the enquiry stage may fruitfully be called in for negotiations to discuss business possibilities and for clarifications of various terms like credit, quantity discount, quality control procedure, etc. Finally, a list of approved and selected vendors is drawn up.

4. Experience Stage

At this stage the buyer evaluates the performance of the vendor. There is a feeling in the minds of many people that the objective supplier evaluation is to shift the good from the bad and leave out the bad. This is not true. The objective is to improve the performance of the vendors in the areas in which they are deficient, such as quality, delivery time, after-sales, etc. It is the same as the annual appraisal of the employees of a company. The idea is to correct their faults and improve their performance. This evaluation is especially on two major counts:

a. Quality

This is judged by the rejection rate of the materials supplied by the vendor, if the rate of rejection is high, it means the vendor is not good enough. Rejections often entail a lot of production problems for the buyer’s company, especially if the material is a high-value item for which usually buffer stocks are low. Production stoppage may occur with its attendant consequences.

b. Delivery

If the delivery is not as per schedule, similar problems can arise. For example, the buyer’s production unit might be working on a tight inventory. If delay in delivery takes place, stock outs may occur.

5. Sample Approval

On satisfactory assessment, the samples obtained are evaluated for dimensions, material property, finish and process.

6. Assistance to Vendors

After the sample is approved, an order is placed. The suppliers are to be provided with special tools, jigs, fixtures and gauges on a selective basis. The gauges have to be calibrated periodically free of cost by the buyer. To assist the sub-contractors in the execution of the jobs, a technical cell should be in operation. The cell should monitor and improve the know-how of the sub-contractors, give them training in the methods of manufacture and quality control techniques.

7. Motivation to Vendors

Vendors are to be encouraged to diversify their line of activity from their initial orientation. For example, a sub-contractor, successful in machining of castings, can be encouraged to take up die casting. Thus, vertical integration can be achieved.

8. Vendor-Vendee get-togethers

Meetings between vendor-vendee and get-togethers enhance mutual trust and cooperation, besides highlighting the status of business order schedules, price and quality. Such regular vendor-vendee interaction can help the senior executives of the organization to have a dialogue with the large number of suppliers, sharing, common problems.